In the era of "machine substitution", many companies have a strong interest in industrial robots, but many companies are not good enough to choose their own industrial robots. Through this article, I hope that everyone can have a general concept towards choosing suitable industrial robots.

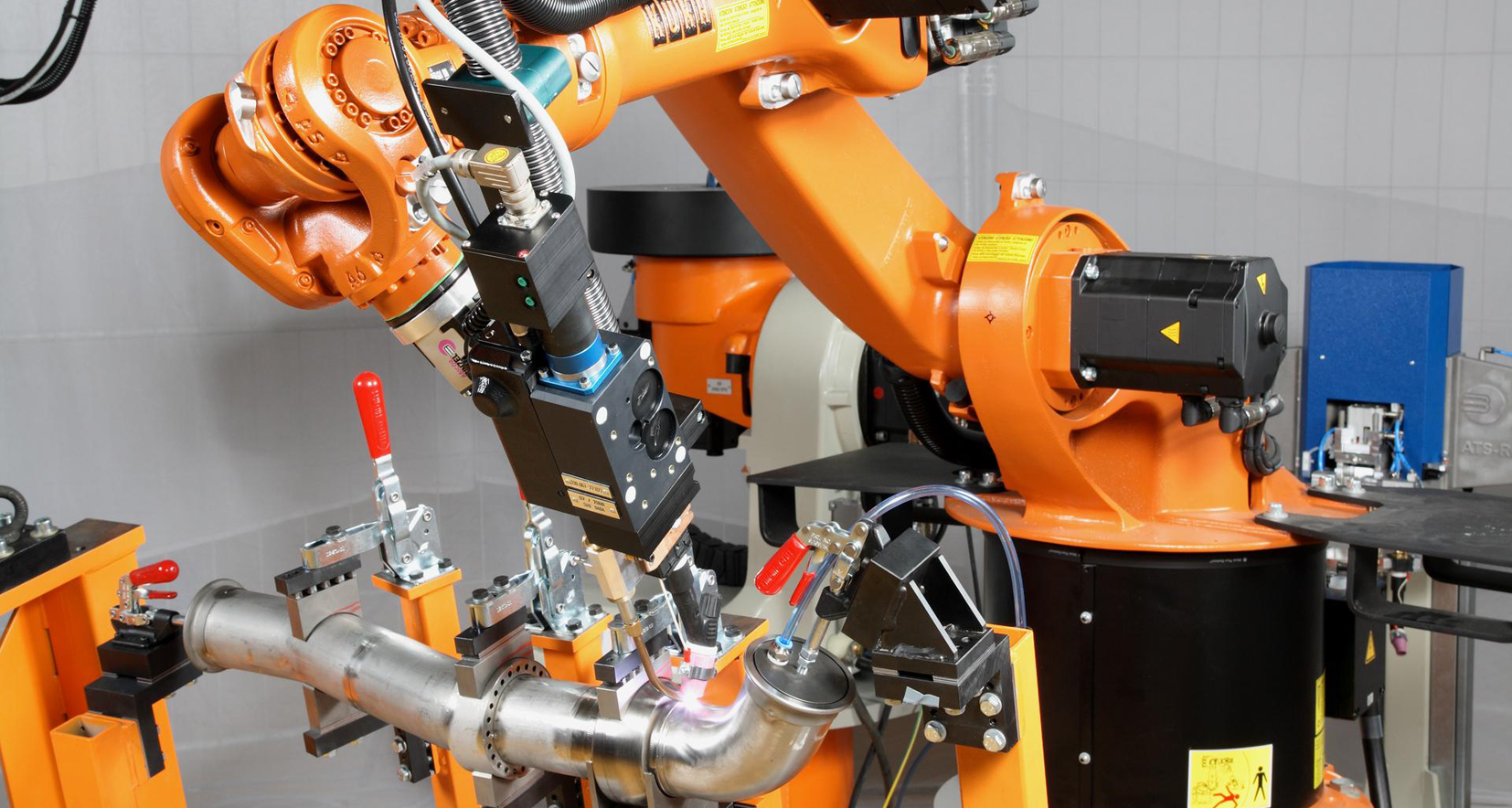

1. Application of the robot

The use of the robot determines the type of robot selected. There are special robots for cutting, handling, welding, etc. You can select the Delta robot if you want to sort out quickly. If you want to carry it in a small space, you can use the SCARA robot. If you want to complete obstacle avoidance during the work process, you need to use a robot with multiple degrees of freedom.

2. Robot's degree of freedom

The degree of freedom of the robot is also the number of axes of the robot. The more the number of axes, the higher the freedom degree of robot, and the stronger the flexibility of robot, therefore, it can do complex work. If it's just for simplely sorting out and placing work, then a four-axis robot is enough. But if you need to do a certain job in a relatively narrow space, then the robot needs to have a lot of flexibility, and a six-axis robot is a good choice. In theory, the more the number of axes, the stronger the flexibility, but the more the number of axes, the more complicated the programming work to be done. This depends on the specific work.

3. Load

The load of the robot determines the maximum weight that the robot can carry while working. You need to know the weight of the accessories on your production line, and then choose the right weight.

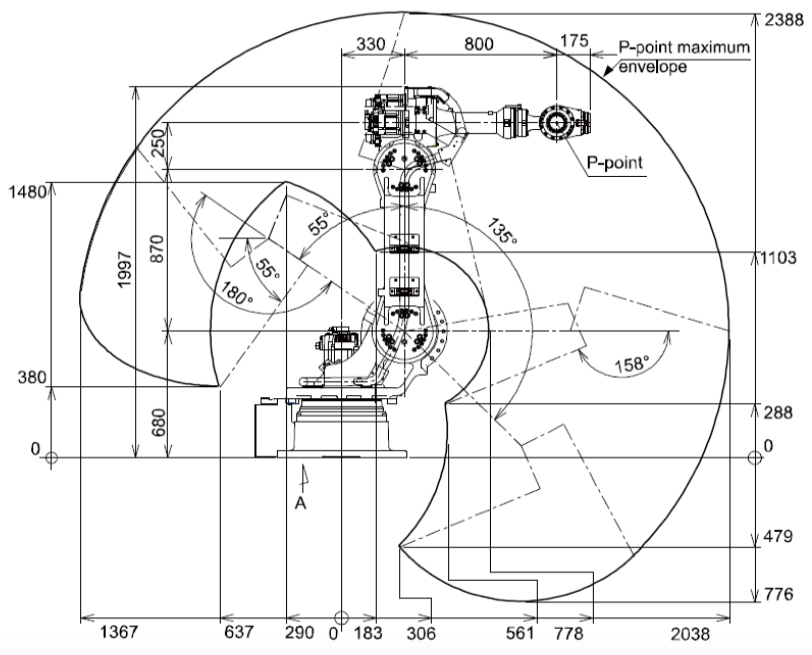

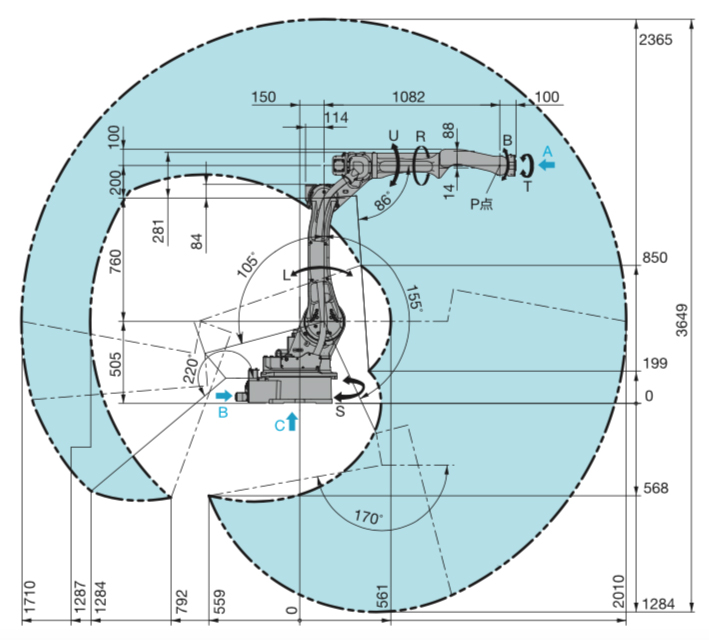

4. Maximum range of motion

Every industrial robot has the largest range of motion and the longest distance that can be reached. It is necessary to consider whether its range of motion meets its own needs.

5. Speed

In general, the maximum speed will be given in the details table. The speed of the robot will be higher and the time for completing the work will be shorter.

6. Repeat positioning accuracy

This parameter directly reflects the accuracy of the robot because there is an error when a robot repeatedly accomplishes a move and reaches a position. Generally speaking, the robot with higher position usually has a smaller error. The general robot error is within ±0.5mm. Therefore, if your application towards precision is accurate, this data needs to be taken seriously again; if the accuracy of the application is not high, there is no need to choose a product with very high repeatable position.

7. Moment of inertia

The moment of inertia in the robot detail table and the allowable torque of each axis have a very important influence on the safe operation of the robot. If the application has certain requirements on the torque, it is necessary to carefully check whether the torque of each axis is satisfied. If the overload may cause the robot, a failure might occurre.

8. Protection level

If the environment used by the robot is dusty or has water that will affect the operation of the robot, then it is important to study the protection degree of the robot. Different robots have different adaptability to various environments. Look at this condition, select a robot suitable for the environment.