| Features |

● Adoption of DSP chips, greatly accelerate the speed of data acquisition and processing.

● Application of large-scale arry circuit improves the reliability.

● Adoption of IPM power device decreases the volume of the driver.

● Monitor function surpports displaying 24 parameters of their state.

● Two input control modes: pulse position and simulation speed.

● Consise appearance and compact structure.

| Performance |

● High speed ratio, constant torque: speed ratio is 1:5000.

● High speed, high precision: max rotate speed up to 3000rpm. Positioning accuracy: 1/10000 rev.

● Out power:0.2~2.2KW.

| Application |

● CNC machine tools: engraving and milling machine, engraving machine, spring machine, spark machine, wire cutting, flying shear equipment etc.

● Electronic equipment: winding machine, wire stripping machine, lithium battery production equipment, dispensing machine, ceramic equipment etc.

● Packaging equipment: glue filling machine, fixed length cutting machine, tissue machine, diaper equipment etc.

● Textile equipment: flat knitting machine, sock machine, round edge machine, embroidery machine, spinning machine, knitting machine etc.

● Printing equipment: screen printing machine, overprinting machine, pad printing machine etc.

● Laser equipment: engraving machine, cutting machine, marking machine etc.

| Technical Parameter |

Servo driver model | SDA06-MF20-□□□ | SDA10-MG20-□□□ | |

Input Power | Single/Three phase | ||

AC220V ( -15%~ +10% ) 50~ 60Hz | |||

Controlling principle | Attains the PWM control by adoptiion of AC sine-wave control and optimal PID control | ||

Feedback Signal | Incremental encoder 2500ppr with U/V/W signal control | ||

Position output signal | Available to set the electronic gear output of pulse rate, and Z-Phase open-collector output | ||

Protection Function | Over-current, short circuit, overload, over / lack voltage of main circuit, abnormal braking, abnormal encoder, overspeed, position error etc. | ||

Control Mode | Position control, speed contol, trial run, JOG run | ||

Regenerative braking resistor | Built-in(60W,40Ω) | ||

Characters | Speed frequency response | 200HZ or more | |

Speed Fluctuation | <0.03(load fluctuation 0~100%);<±0.02(power fluctuation-15~+10%)(datamatches the rated speed) | ||

Speed Ratio | 1:5000 | ||

Pulse Frequency | ≤500kHz | ||

Control Input | ①Servo on ② alarm reset ③ clock wise rotation driver prohibted ④ counterclockwise driver prohibited ⑤ error counter clear / internal speed selection 1 ⑥ pulse command prevented/ internal speed selection 2 ⑦ multifunctional input port 1 ⑧ multifunctional input port 2 | ||

Control output | servo ready, servo alarm, positioning finished / speed reached | ||

Position Control | Input mode | Pulse command + symbol, clockwise pulse / counterclockwise pulse, 2 phase orthogonal instruction phase | |

Electronic gear | 1~32767/1~32767 | ||

Feedback pulse | 10000p/r | ||

Speed Contol | External command / 4 internal speed control | ||

Acceleration / Deceleration control | Parameter setting 1~10000ms/1000r/min | ||

Monitoring function | Speed, current position, position command, position deviation, motor torque, motor current, linear speed, position control, pulse frequency under position command, running state etc | ||

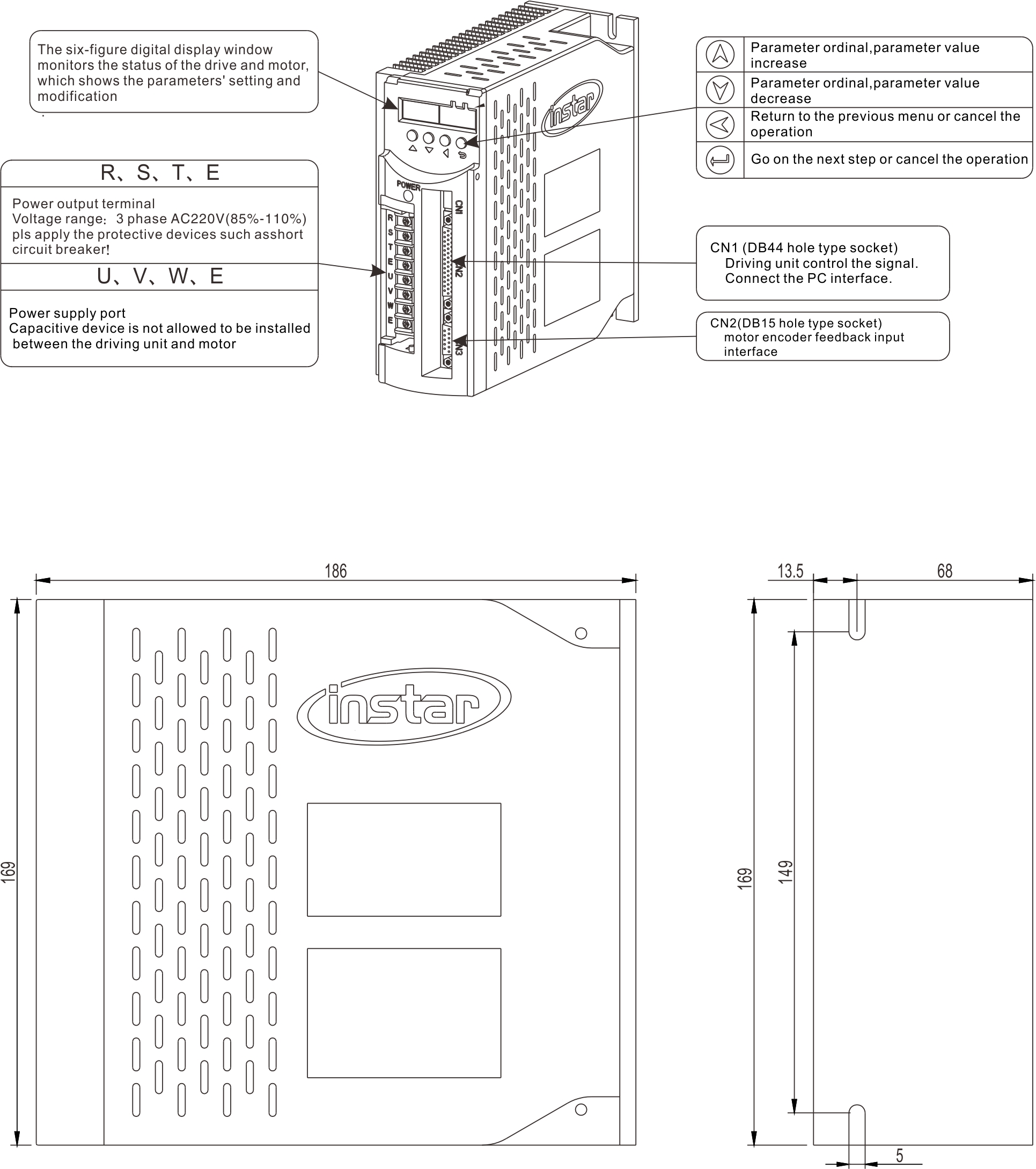

Operation | LED digital tube, keystroke | ||

Weight | 2kg | ||

Working enviroment | Temperature | Working environment:0~50℃ Storage environment:-20℃~65℃ | |

Humidity | Less 90%(No condensation) | ||

Altitude | ≤1000meters | ||

Vibration | Less 0.5G(4.9m/S2),10~60Hz(not continuous running) | ||

※ Please discuss with us or our agents if there is any other special requirements.

| Dimension |

中文

中文 繁體

繁體