| Features |

● Up to 64 drives can be mounted using the RS485 Modbus-RTU bus protocol

● Built-in single-axis controller and driver functions for position control, speed control and multi-segment position control

● 16 selections of uniform angle and constant torque subdivisions, the max resolution up to 52100 steps/rev.

● 2-channel opto-isolation can program high-speed differential input interface, and 2-channel opto-isolated output interface

● Adoption of 4-wires-control circuit greatly reduces noise and increases the rotation stability

● The max response frequency up to 200KHz

● Bipolar constant current chopper control improves the output speed and power of the motor

● When the steper pulse stops for more than 100ms, the coil current is automatically halved, which reduces the overheating of the stepper motor.

● Bipolar constant current chopper control improves the output speed and power of motor.

● Current range: 0.1A~5A

● Single power input, voltage: DC24~50V(The optimal voltage is DC48V)

● Signal source voltage: DC3.3~28V(Any input will be fine, no external current limiting resistor is required)

● Error protection: ① Low supply voltage ② High supply voltage ③ Phase open circuit ④ Phase overcurrent ⑤ Encoder fault

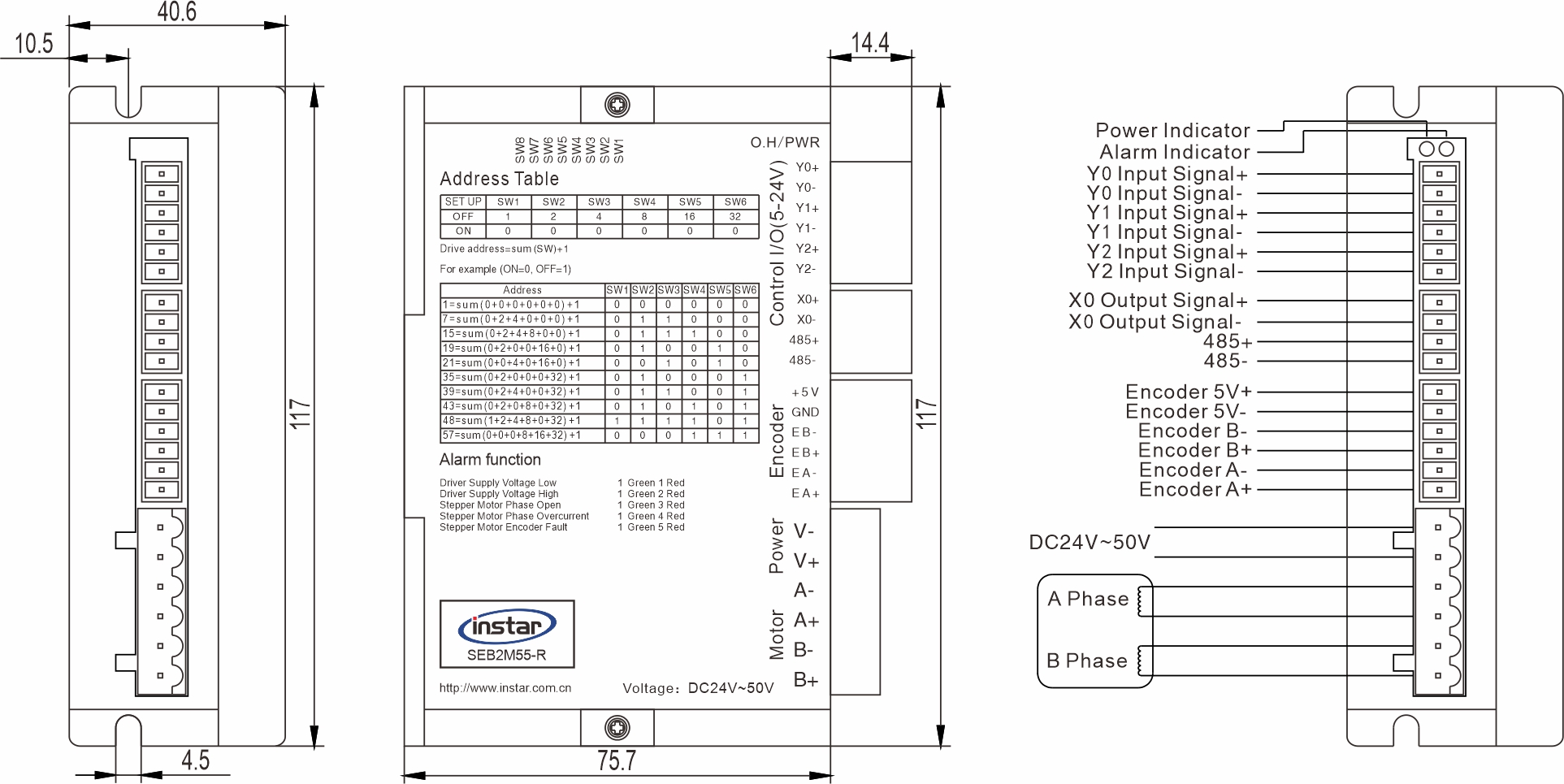

● Size: 117×75.7×40.6(mm), Net weight: 0.29kg

| Description |

SEB2M55-R RS485 Modbus-RTU closed-loop stepper driver increses bus communication and single shaft control function on basis of closed-loop stepper driver.

The bus closed-loop stepper driver can completely replace the closed-loop stepper driver with traditional pulse direction control function, and in-built driver bus communication function, which takes the Modbus-RTU bus communication so that the users can control 64 pieces of drivers at the same time. Besides, the updated closed-loop stepper driver has planty input / output connectors for accomplishing single-shaft control function like the position control, speed control, and returning function etc. Compared to traditional closed-loop stepper driver, this bus closed-loop stepper driver is suitable for the the machion needing many pieces of drivers, far distance and strong signal interference condition. Closed-loop stepper driver voltage is DC24V~50V(The optimal voltage is DC48V), which adops single-phase power suitable for single-phase closed loop stepper motor with 56mm~60mm external diameter under 5A.

Based on the load current control technoloy, it can effectively prolong the service life of the motor. Position arival signal and alarm signal has built into the driver to faciliate the monitoring and control of the controller.

| Application |

Woodworking engraving machine, laser engraving machine, marking machine, labeling machine, solid crystal machine, wire bonding machine, UV printer, 3D printer, inkjet printer, plotter, embroidery machine, dispensing machine, glue filling machine, soldering machine, BGA rework station, laminating machine, placement machine, hot press, backlight laminating machine, coating machine, reciprocating machine, terminal machine, stripping machine, winding machine, solder paste printing machine, PCB drilling machine, V -CUT machine, target machine, FPC reinforcement machine, coating machine, lamination machine, IC sorting machine, IC burner, tape machine, medical equipment, non-standard equipment, XYZ measuring instrument, connector assembly machine, SMT peripheral equipment etc.

| Communication Address Setting Table |

Address | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

D1 | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF |

D2 | ON | ON | OFF | OFF | ON | ON | OFF | OFF | ON | ON | OFF | OFF | ON | ON | OFF | OFF |

D3 | ON | ON | ON | ON | OFF | OFF | OFF | OFF | ON | ON | ON | ON | OFF | OFF | OFF | OFF |

D4 | ON | ON | ON | ON | ON | ON | ON | ON | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF |

D5 | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON |

D6 | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON |

Address | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 |

D1 | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF |

D2 | ON | ON | OFF | OFF | ON | ON | OFF | OFF | ON | ON | OFF | OFF | ON | ON | OFF | OFF |

D3 | ON | ON | ON | ON | OFF | OFF | OFF | OFF | ON | ON | ON | ON | OFF | OFF | OFF | OFF |

D4 | ON | ON | ON | ON | ON | ON | ON | ON | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF |

D5 | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF |

D6 | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON |

Address | 33 | 34 | 35 | 36 | 37 | 38 | 39 | 40 | 41 | 42 | 43 | 44 | 45 | 46 | 47 | 48 |

D1 | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF |

D2 | ON | ON | OFF | OFF | ON | ON | OFF | OFF | ON | ON | OFF | OFF | ON | ON | OFF | OFF |

D3 | ON | ON | ON | ON | OFF | OFF | OFF | OFF | ON | ON | ON | ON | OFF | OFF | OFF | OFF |

D4 | ON | ON | ON | ON | ON | ON | ON | ON | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF |

D5 | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON | ON |

D6 | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF |

Address | 49 | 50 | 51 | 52 | 53 | 54 | 55 | 56 | 57 | 58 | 59 | 60 | 61 | 62 | 63 | 64 |

D1 | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF |

D2 | ON | ON | OFF | OFF | ON | ON | OFF | OFF | ON | ON | OFF | OFF | ON | ON | OFF | OFF |

D3 | ON | ON | ON | ON | OFF | OFF | OFF | OFF | ON | ON | ON | ON | OFF | OFF | OFF | OFF |

D4 | ON | ON | ON | ON | ON | ON | ON | ON | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF |

D5 | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF |

D6 | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF |

| Dimension |

| Pin Functions |

Mark | Funcion | Instruction |

POWER | Power indicator | Power on, the green indicator normally on |

O.H | Fault indecator | Overcurrent 、phase open circuit, over voltage, low voltage, the red indicator flashes. |

PU+ | Input signal positive side | connects +3.3V~+28V pulse signal power. |

PU- | Pulse signal | When the falling edge is valid, the motor moves a step as the pulse become lower, input resistance is 220Ω. Requires: low level +0v~+0.5v, high level+4v~+5v, pulse width>2.5μs |

DR+ | Input signal positive side | Connects +3.3V~+28V pulse signal power |

DR- | Direction control signal | For changing the direction, input resistance is 220Ω. Requires: low level+0V~+0.5V, high level+4V~+5V, pulse width >2.5μs. |

MF+ | Input signal positive side | Connects+3.3V~+28V pulse signal power |

MF- | Motor free signal | When the low electrical level is valid, it cuts off the motor current, the driver stops working and motor will be in a free state. |

ALM+ | Alarm signal positive side | Overcurrent, phase open circuit, over voltage, low voltage, position deviation alarm, in-position signal is valid (output optocoupler is turned on). ALM+ connects to the positive pole, ALM- connects to the negative pole, max current 10mA. |

ALM- | Alarm signal neg tive side | |

Pend+ | In-position signal output positive terminal | The in-position signal is valid when the driver has finished a given pulse (output optocoupler is turned on) Pend+ is connected with resistor to the positive pole of the output power supply, and Pend- is connected to the negative pole of the output power supply. The maximum driver current is 10mA. |

Pend- | In-position signal output negtive terminal | |

+V | Power+ | DC24~50V(The optimal voltage is DC48V) |

-V | Power- | |

+A、-A | Connect to the motor | Please refer to the motor connections. |

+B、-B |

| Alarm functions |

● When 1 Green and 1 Red flashes, it means that the power supply voltage of the closed-loop driver is low; solution: check whether the power supply voltage of the closed-loop driver is too low;

● When 1 Green and 2 Red flashes, it means that the power supply voltage of the closed-loop driver is high; solution: check whether the power supply voltage of the closed-loop driver is too high;

● When 1 Green and 3 Red flashes, it means that the phase of the closed-loop stepping motor is open; the solution: check whether the wiring of the closed-loop stepping motor is wrong;

● When 1 Green and 4 Red flashes, it means that the closed-loop stepper motor phase is over-current; solution: check whether the closed-loop driver MOS tube is damaged or whether the closed-loop stepper motor is damaged;

● When 1 Green and 5 Red flashes, it means the closed-loop stepper motor encoder is faulty; solution: check whether the closed-loop stepper motor encoder is wired correctly and whether it is damaged;

● When 1 Green and 6 Red flashes, it means that the feedback position of the closed-loop stepping motor encoder is out of tolerance; solution: check whether the closed-loop stepping motor loses steps;

● When 1 Green and 7 Red flashes, it means the closed-loop driver has other faults; solution: send it back to the manufacturer for inspection;

The driver will loe self-locking function when the above alarms start, please clear faults and re-up electricity, the driver goes back to normal when the green power indicator normally on.

▲ Attention: the driver canot be protective when connects the wire inversely or wrongly, please confirm the connections before electrify it, otherwise the fuse inside may be burnout.

中文

中文 繁體

繁體