| Features |

● High performance, low noise, affordable price, high speed and torque, excellent stability

● 16 selections of uniform angle and constant torque subdivisions, the max resolution up to 60000 steps/rev

● Adoption of 3-wires-control circuit greatly reduces noise and increases the rotation stability

● The max response frequency up to 200Kpps

● Once the pulse stops for more than 100ms, the coil current will be reduced to 20%~80% ( set by STOP ) automatically

● Bipolar constant current chopper control improves the output speed and power of the motor

● Optically isolated signal I / O

● Current range: 0.6A~4.2A / be devided into 16 grades

● Single power input, voltage range :AC110~220V ( The optimal voltage is AC220V )

● Error Protection: ① Overheat protection ② Overcurrent ③ Low voltage protection

● Size:178×118.5×68(mm), Net weight:1.25kg

| Description |

SEA3D420 is a microstep motor driver with uniform angle and constant torque subdivisions, voltage range is AC110~220V ( the optimal voltage is AC220V ), single power supply. It matches 3 phase hybrid stepper motors which rated current under 4.2A, external diameter 86mm~130mm, and outlets 3 or 6.

Bipolar constant current chopper control makes the motor run smoothly with lower noise and higher stability; The increase of the voltage greatly improves the drive capability and speed. The coil current will be automatically reduced to 20%~80% ( set by STOP ) onece the pulse stops for more than 100ms, it reduces the heat of driver by 50%, reduces the heat of motor as well. Users can choose low speed high subdivision which up to 60000 steps/rev, it improves the precision, reduces the vibration and noise.

| Application |

Woodworking engraving machine, laser engraving machine, marking machine, labeling machine, solid crystal machine, wire bonding machine, UV printer, 3D printer, inkjet printer, plotter, embroidery machine, dispensing machine, glue filling machine, soldering machine, BGA rework station, laminating machine, placement machine, hot press, backlight laminating machine, coating machine, reciprocating machine, terminal machine, stripping machine, winding machine, solder paste printing machine, PCB drilling machine, V -CUT machine, target machine, FPC reinforcement machine, coating machine, lamination machine, IC sorting machine, IC burner, tape machine, medical equipment, non-standard equipment, XYZ measuring instrument, connector assembly machine, SMT peripheral equipment etc.

| Pulse Setting List |

SK | F | E | D | C | B | A | 8 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 0 |

Pulse / rev | 400 | 500 | 600 | 800 | 1000 | 1200 | 2000 | 3000 | 4000 | 5000 | 6000 | 10000 | 12000 | 20000 | 30000 | 60000 |

| DIP switch function setting |

DP1 | OFF:accept external pulse signal; ON:driver send 7.5KHz pulse, then the microstep should be set to be 2000-10000 |

DP2 | OFF:pulse signal+direction signal control ON:clockwise pulse+counter clockwise pulse control |

| Current Setting |

1. STOP/Im is stable state current adjuster, it can be set to 20%~80% of the normal output current ( Adjusting it clockwise will increase the current and counterclockwise decrease current )

2. RUN/Im is normal running current adjuster ( please check the details as follows )

RUN/Im | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | A | B | C | D | E | F |

Im (A) | 0.7 | 1.1 | 1.5 | 2.0 | 2.4 | 2.8 | 3.2 | 3.6 | 4.0 | 4.5 | 5.0 | 5.4 | 5.8 | 6.2 | 6.6 | 7.0 |

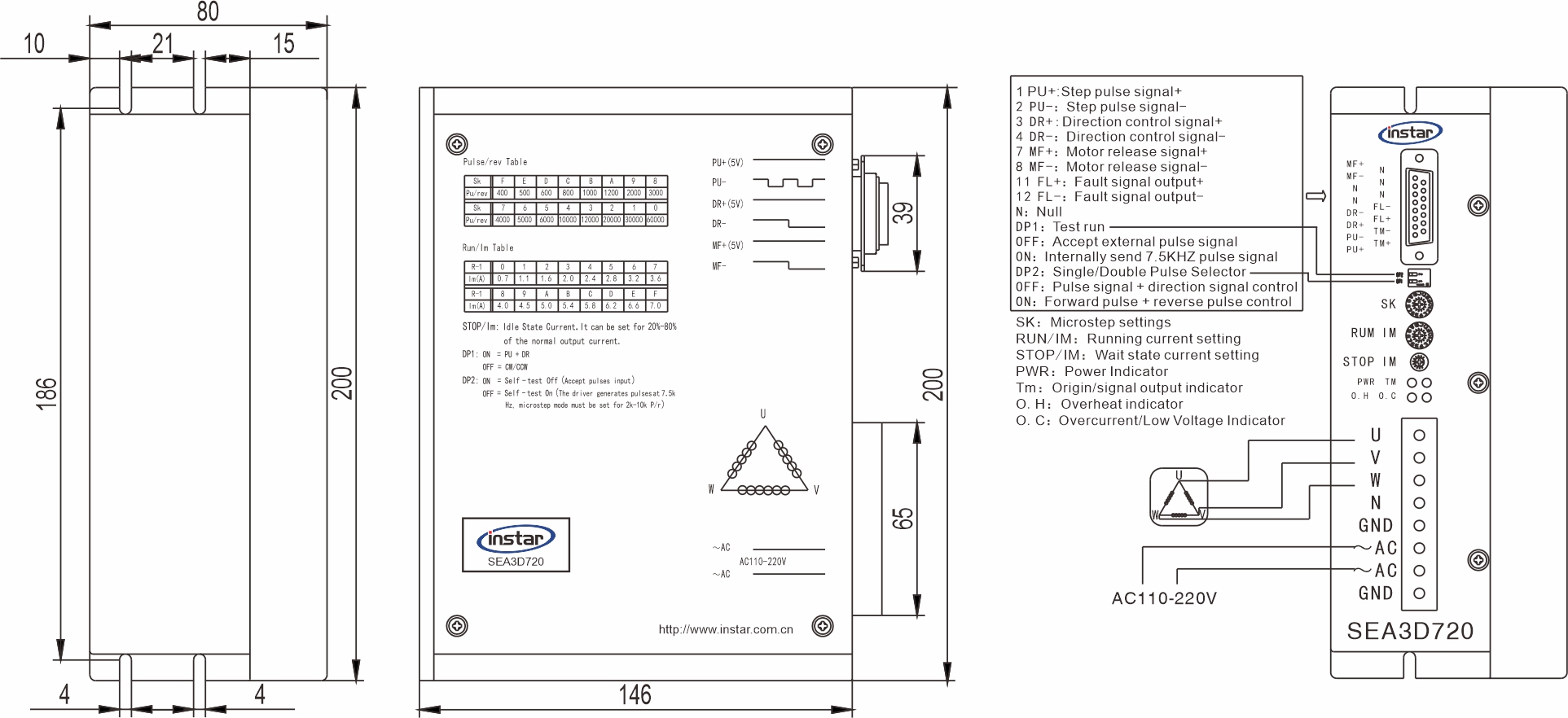

| Dimension |

| Pin Functions |

Mark | Functions | Instruction |

POWER | Power Indicator | Power on, the green indicator normally on. |

TM | Working indicator light | When the pulse frequency is low, the green indicator flashes, when the pulse frequency is high, the green indicator normally on. |

O.H | Overheat indicator | The Temperature rise exceeds 70 ℃, the red indicator normally on. |

O.C | Overcurrent / Low voltage indicator | The current exceeds rated value or the voltage is lower than rated value, the red indicator normally on. |

Im | Phase current setting adjuster | Set the phase current, clockwise it increases, anticlockwise it dereases. |

PU+ | Input signal positive side | For changing the direction,input resistance is 220 Ω. Requires: low level +0V~+0.5V, high level+4V~+5V, pulse width >2.5 μs. |

PU- | DP2=OFF, PU is pulse signal | When the falling edge is valid, the motor moves a step as the pulse become lower, input resistance is 220Ω. Requires: low level +0V~+0.5V, high level +4V~+5V, pulse width >2.5 μs. |

DP2=ON,PU is clockwise pulse signal | ||

DR+ | Input signal positive side | For changing the direction,input resistance is 220 Ω. Requires: low level +0V~+0.5V, high level+4V~+5V, pulse width >2.5 μs |

DR- | DP2=OFF, direction control signal | Pulse signal power supply should in the range of +5V~+24V, if higher than +5V needs to add a resistor. |

DP2=ON, counter clockwise pulse signal | ||

MF+ | Input signal positive side | Pulse signal power supply should in the range of +5V~+24V, if higher than +5V needs to add a resistor. |

MF- | Motor free signal | When the low electrical level is valid, it cuts off the motor current, the driverstops working and motor will be in a free state. |

TM+ | Origin input signal positive side | The signal is valid when the motor pass electrical origin. |

TM- | Origin output signal negative side | TM+ connects resistor, TM- connects GND, the max output current is 50mA, the max voltage is 50V. |

RDY+ | Driver ready signal positive side | Pulse signal power supply should in the range of +5V~+24V, if higher than +5V needs to add a resistor. |

RDY- | Driver ready signal negative side | It's valid when the driver is in normal state and ready for accecpting signals from controller. |

AC | Power | AC110~220V ( The optimal voltage is AC110V ) |

AC | ||

GND | Ground wire | Ground( The driver housing is connected inside ) |

U | Connect the motor | Please refer to motor connections |

V | ||

W |

| Attention |

1. Please do not reverse the power supply, input voltage not more than AC230V;

2. The input control signal level is +5V, if higher than +5V, needs to add a resistor on PU-, DR-, FM- ( do not add on + sides );

3. This model of the driver uses a special control circuit, so it matches stepper motor of 6 or 8 outlets only;

4. The driver will automatically stop working when the temperature exceeds 70 degrees, the O.H indicator light normally on, temperature drops to 50 degrees it automatic recovers to work, please install radiator when it's in overheating protection;

5. When the current exceeds rated value or the voltage is lower than rated value, the O.C indicator light normally on, please check the connections and other short troubles needs to re-up power after the faults cleared, or if the power voltage is too low;

6. The PWR green indicator light normally on when the driver is powered on;

7. The TM indicator light comes on when the pulse input go crossing the zero point.

中文

中文 繁體

繁體