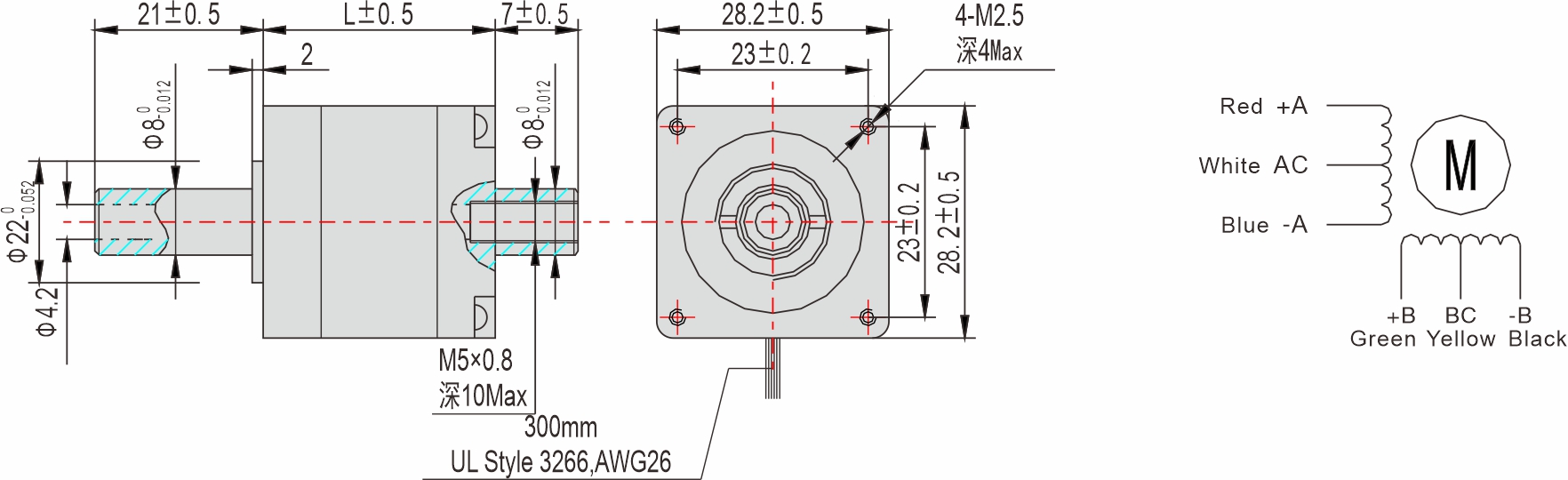

| Dimension (Unipolar coil) |

※ We can customize the parameters of stepper motor as your order

※ Spigot installation with front cover is a must when seting up the motor, besides tolerance fiding should be taken into account , to secure the concentricity of output shaft and motor output.

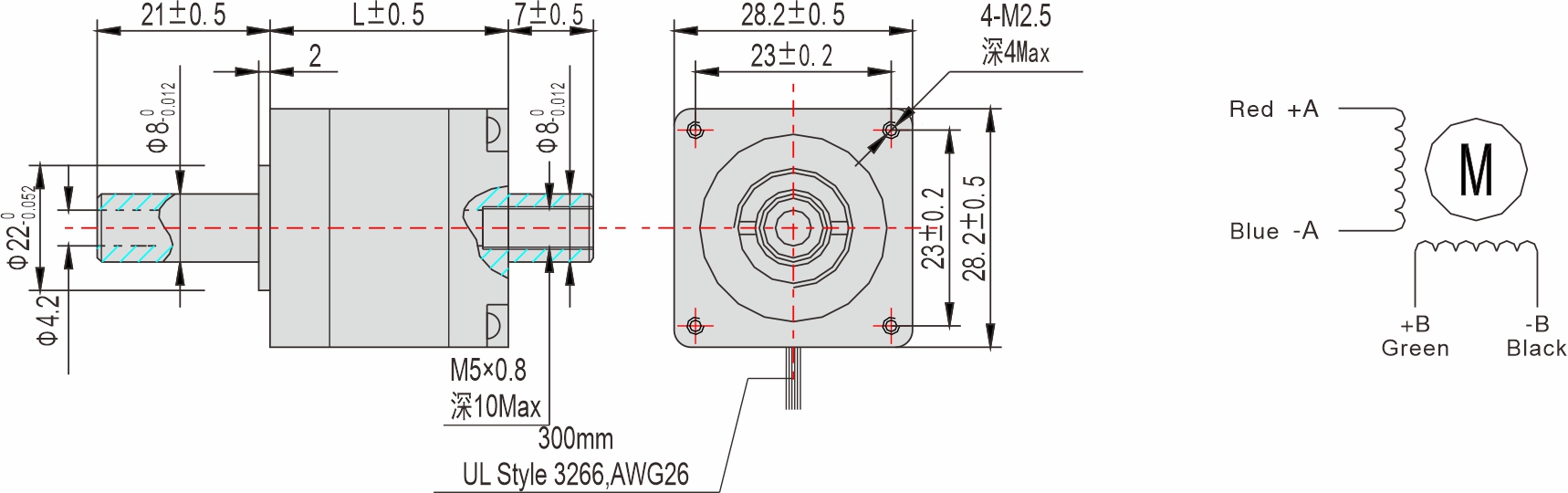

| Dimension (Bipolar coil) |

※ We can customize the parameters of stepper motor as your order

※ Spigot installation with front cover is a must when seting up the motor, besides tolerance fiding should be taken into account , to secure the concentricity of output shaft and motor output.

| 20mm |

Model | Size | Weight (kg) | |||

L(mm) | |||||

YSD212-XXX | 28 | 0.1 | |||

YSD213-XXX | 34 | 0.11 | |||

YSD214-XXX | 41 | 0.15 | |||

YSD215-XXX | 51 | 0.2 |

| Technical Parameters (Unipolar coil) |

Stepper Motor Model | Driver Model | Current / Phase | Resistance / Phase | Inductance / Phase | Holding Torque | Lead | Rotor inertia | Weight | Length | |

A | Ω | mH | kg-cm | g-cm2 | Kg | L(mm) | ||||

YSD212-HB6 | 0.67 | 4.2 | 1.77 | 0.3 | 6 | 6 | 0.1 | 28 | ||

YSD213-HB6 | 0.67 | 5.8 | 2.5 | 0.45 | 6 | 9 | 0.11 | 34 | ||

YSD214-HB6 | 0.67 | 7.5 | 3.6 | 0.6 | 6 | 12 | 0.15 | 41 | ||

YSD215-HB6 | 0.67 | 8.2 | 4 | 0.8 | 6 | 18 | 0.2 | 51 | ||

| Technical Parameters (Bipolar coil) |

Stepper Motor Model | Driver Model | Current / Phase | Resistance / Phase | Inductance / Phase | Holding Torque | Lead | Rotor inertia | Weight | Length | |

A | Ω | mH | kg-cm | g-cm2 | Kg | L(mm) | ||||

YSD212-HB4 | 0.67 | 4.7 | 4.7 | 0.45 | 4 | 6 | 0.1 | 28 | ||

YSD213-HB4 | 0.67 | 6.2 | 6.2 | 0.6 | 4 | 8 | 0.11 | 34 | ||

YSD214-HB4 | 0.67 | 7 | 6 | 0.8 | 4 | 12 | 0.15 | 41 | ||

YSD215-HB4 | 0.67 | 9 | 7 | 1 | 4 | 18 | 0.2 | 51 | ||

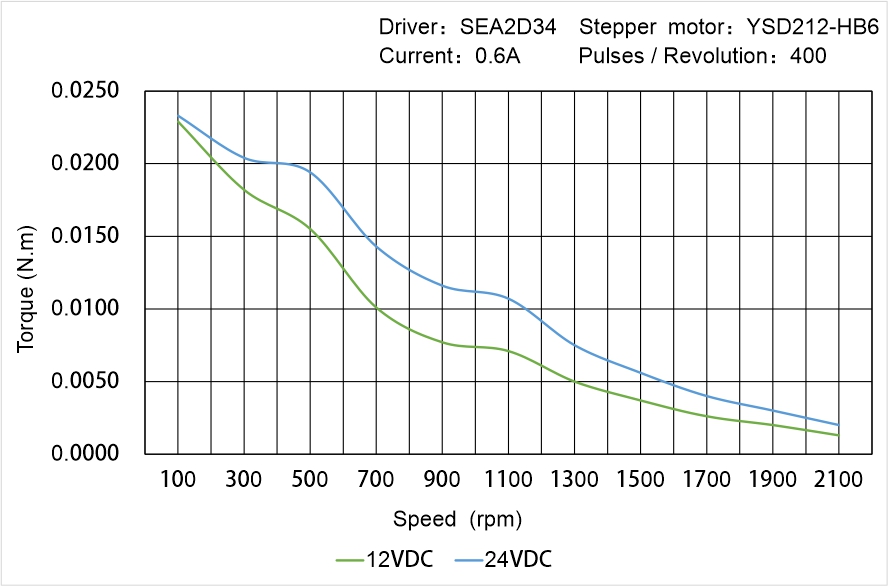

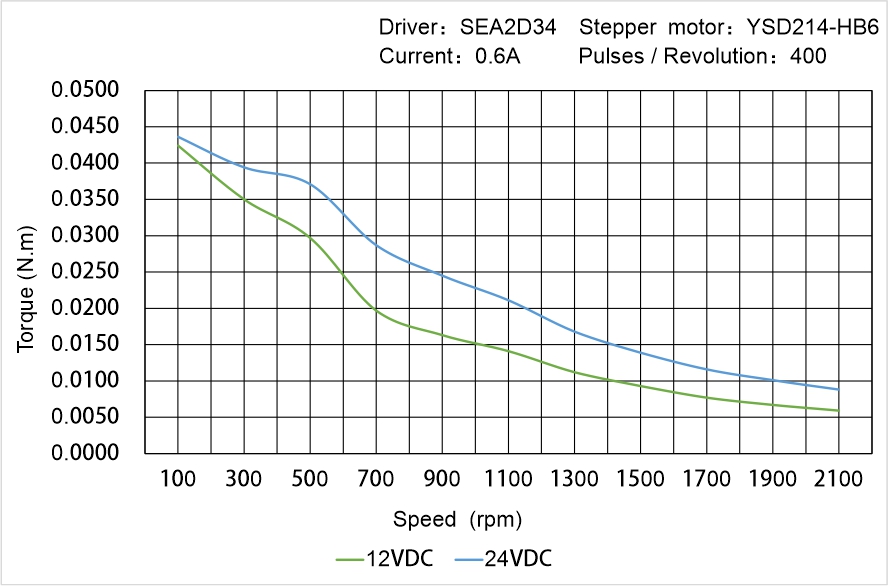

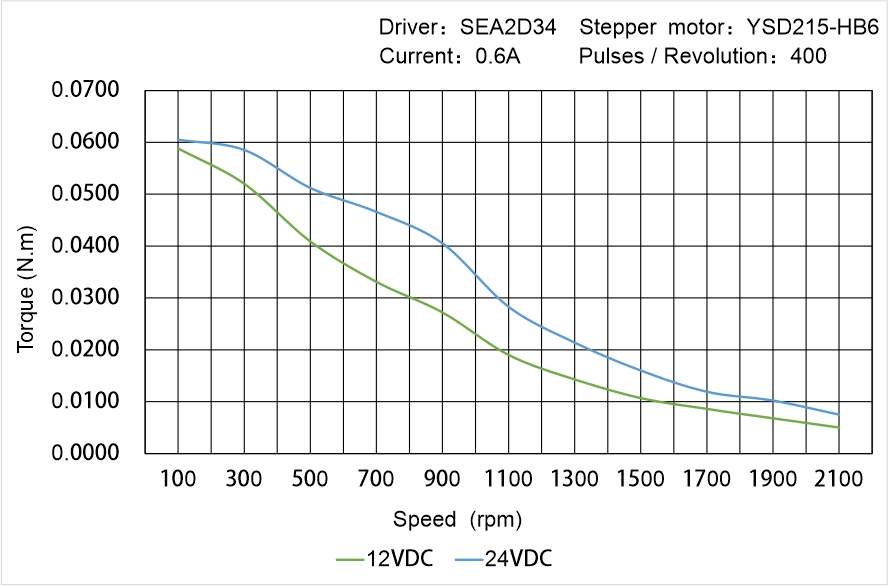

| Speed - Torque Characteristics(Unipolar coil) |

※ Speed Torque Characteristics are data based on our company's measurement conditions. When conditions change, Speed Torque Characteristics may change.

※ Stepper motors can generate a lot of heat due to different driving conditions. Please use it when the stepper motor case temperature is below 100°C.

※ Please set the set current of the driver below the rated current of the stepper motor.

|

| |

|

|

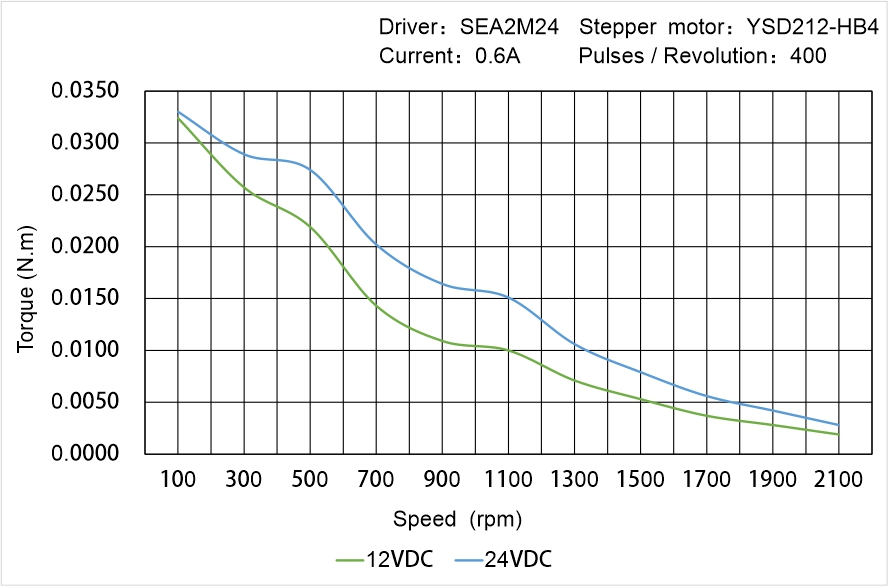

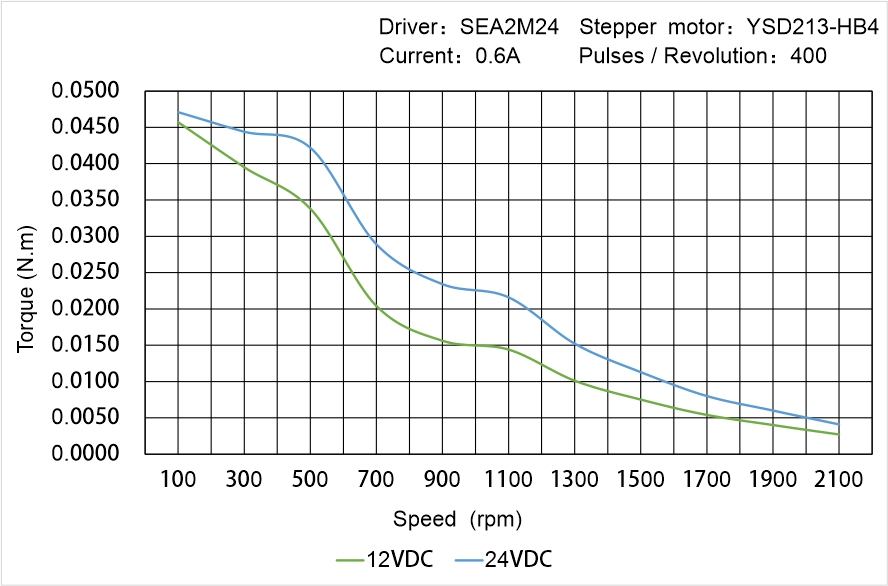

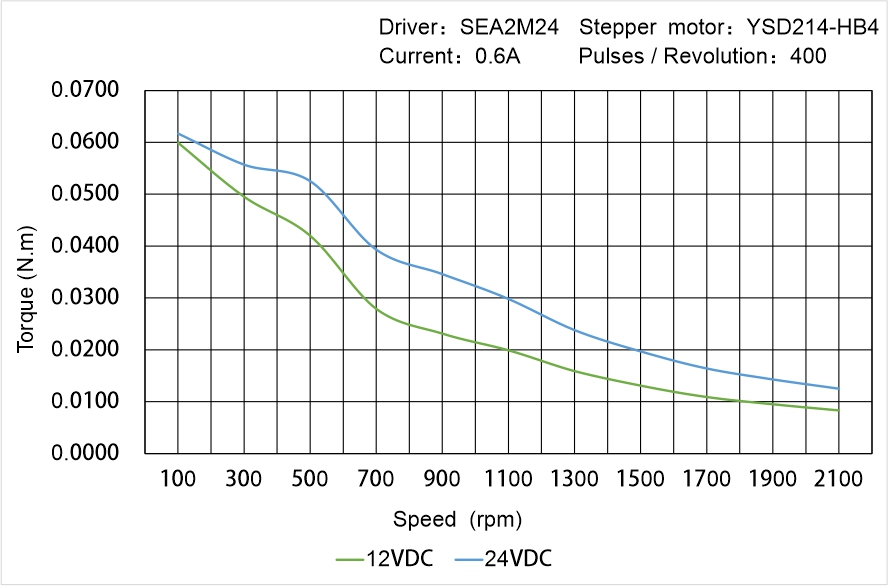

| Speed - Torque Characteristics(Bipolar coil) |

※ Speed Torque Characteristics are data based on our company's measurement conditions. When conditions change, Speed Torque Characteristics may change.

※ Stepper motors can generate a lot of heat due to different driving conditions. Please use it when the stepper motor case temperature is below 100°C.

※ Please set the set current of the driver below the rated current of the stepper motor.

|

| |

|

|

| Optional Accessories |

Motor power line:

Model | Length(m) | Conductor(m㎡) |

SEB-PC050-01E | 1 | 0.5 |

SEB-PC050-02E | 2 | |

SEB-PC050-03E | 3 | |

SEB-PC050-04E | 4 | |

SEB-PC050-05E | 5 | |

SEB-PC050-07E | 7 | |

…… | …… | |

SEB-PC050-10E | 10 |

※ 10 million times ultra-flexible drag chain cable with crimped connector used for connection between stepper motor and driver.

The wiring distance between the stepper motor and the driver should be controlled within 10m.

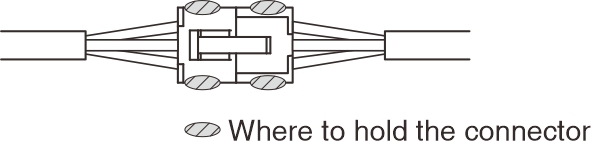

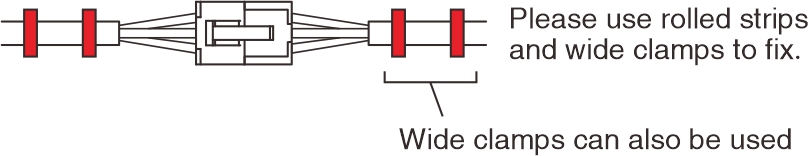

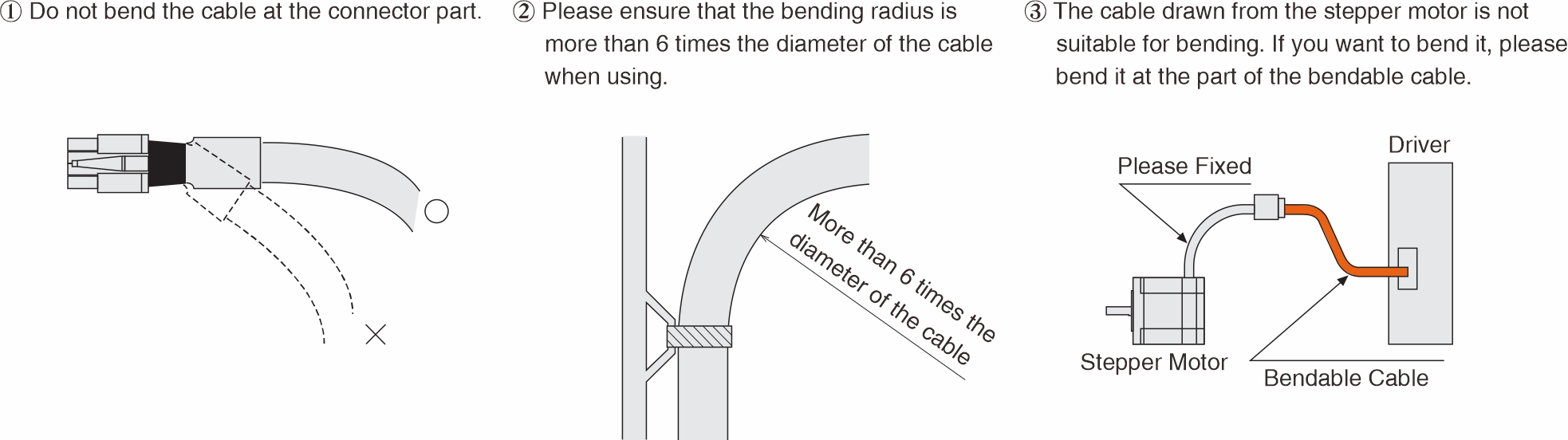

| Precautions For Cables |

|

| |

When plugging and unplugging the connector, be sure to hold the connector for operation. If you pull on the cable, it may cause poor contact. | Do not bend the cable at the connector part, if stress is applied to the connection part or the terminal, it may cause poor contact or disconnection. Please fix the red two connector parts to prevent the connector parts from shaking, which may cause terminal damage or poor contact. | |

|

| |

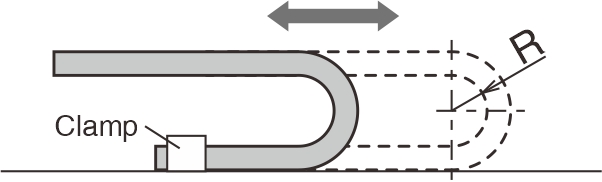

When plugging in the connector: Hold the connector body and insert it straight. If inserted at an angle, it may cause terminal damage or poor contact. When unplugging the connector: Please unlatch the connector first, then pull it straight out. If you hold the cable and pull it out, the connector may be damaged. | Please use the appropriate length for wiring so that the cable will not be pulled when moving. In addition, please make sure that the bending radius R is above the cable diameter of 6. |

| Technical Parameters |

Item | Instructions |

Step angle | 1.8゜ |

Step angle accuracy | ±5% (full step, no load) |

Resistance accuracy | ±10% |

Inductance accuracy | ±20% |

Temperature rise | 80℃ Max (rated current, 2 phase on) |

Ambient temperature | -20℃~+50℃ |

Insulation resistance | 100MΩ Min500VDC |

Dielectric strength | 500V AC for one minute |

Shaft Radial Force | 0.02Max (450g load) |

Axial Play | 0.08Max (450g load) |

Max Radial Force | 28N (20mm from the flange) |

Max Axial Force | 10N |

| Application |

Woodworking engraving machine, laser engraving machine, marking machine, labeling machine, solid crystal machine, wire bonding machine, UV printer, 3D printer, inkjet printer, plotter, embroidery machine, dispensing machine, glue filling machine, soldering machine, BGA rework station, laminating machine, placement machine, hot press, backlight laminating machine, coating machine, reciprocating machine, terminal machine, stripping machine, winding machine, solder paste printing machine, PCB drilling machine, V -CUT machine, target machine, FPC reinforcement machine, coating machine, lamination machine, IC sorting machine, IC burner, tape machine, medical equipment, non-standard equipment, XYZ measuring instrument, connector assembly machine, SMT peripheral equipment etc.

中文

中文 繁體

繁體